PUF Sandwich Panels

Structured Efficiency for Industrial Construction

Technical Next-Generation Construction Core

"PUF Sandwich Panels, or Polyurethane Foam Panels, are a popular choice in the construction world for both residential and commercial projects."

At PULUX Industries, our PUF panels are crafted by skilled experts who pay close attention to every detail. This ensures a top-notch product that boasts durability and longevity. Each panel is made up of three distinct layers of polyurethane foam. This makes them sturdy and a fantastic option for anyone looking for better building materials.

Our PUF Panels are lightweight, which simplifies installation compared to traditional materials. They are produced using advanced machinery and seasoned professionals, allowing them to last for decades with minimal upkeep. Designed to be water-resistant, PULUX panels can handle extreme weather conditions, protecting your belongings from the elements.

Advanced Composition & Technology

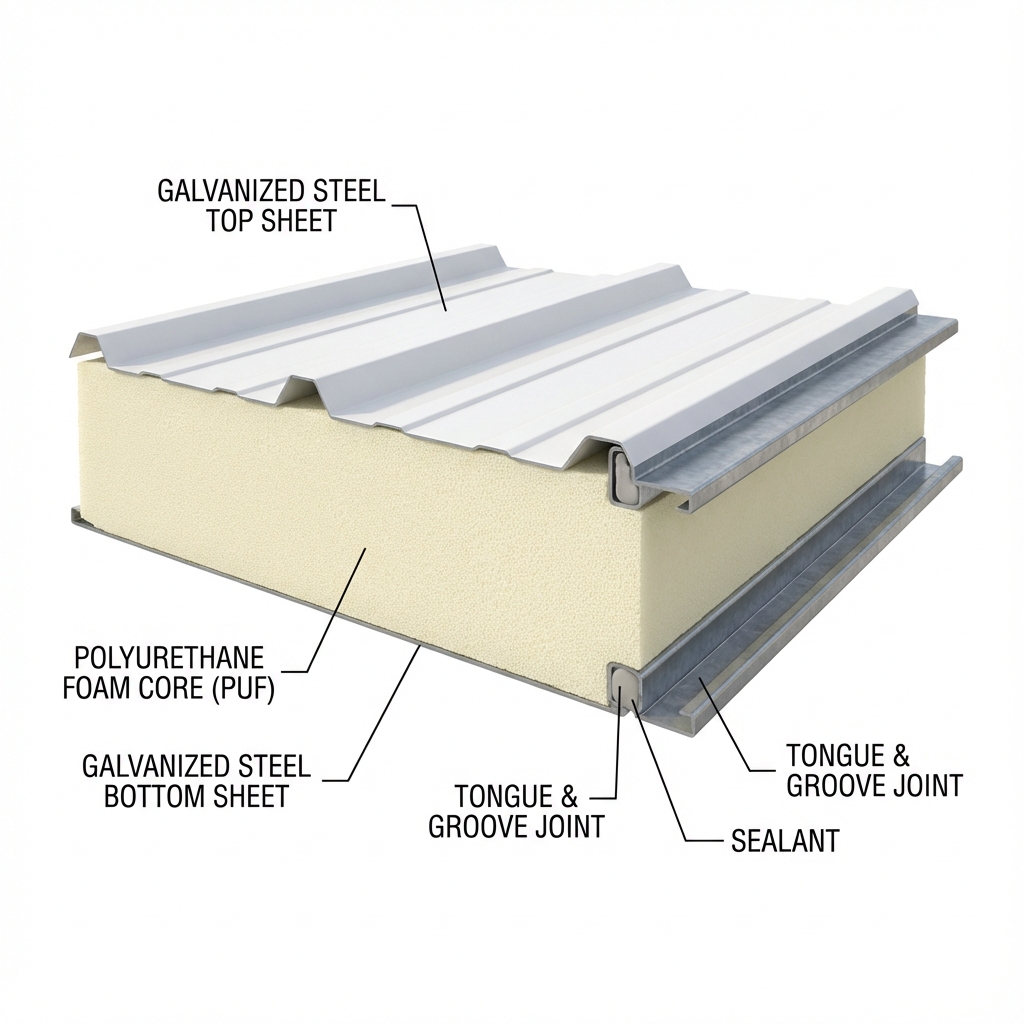

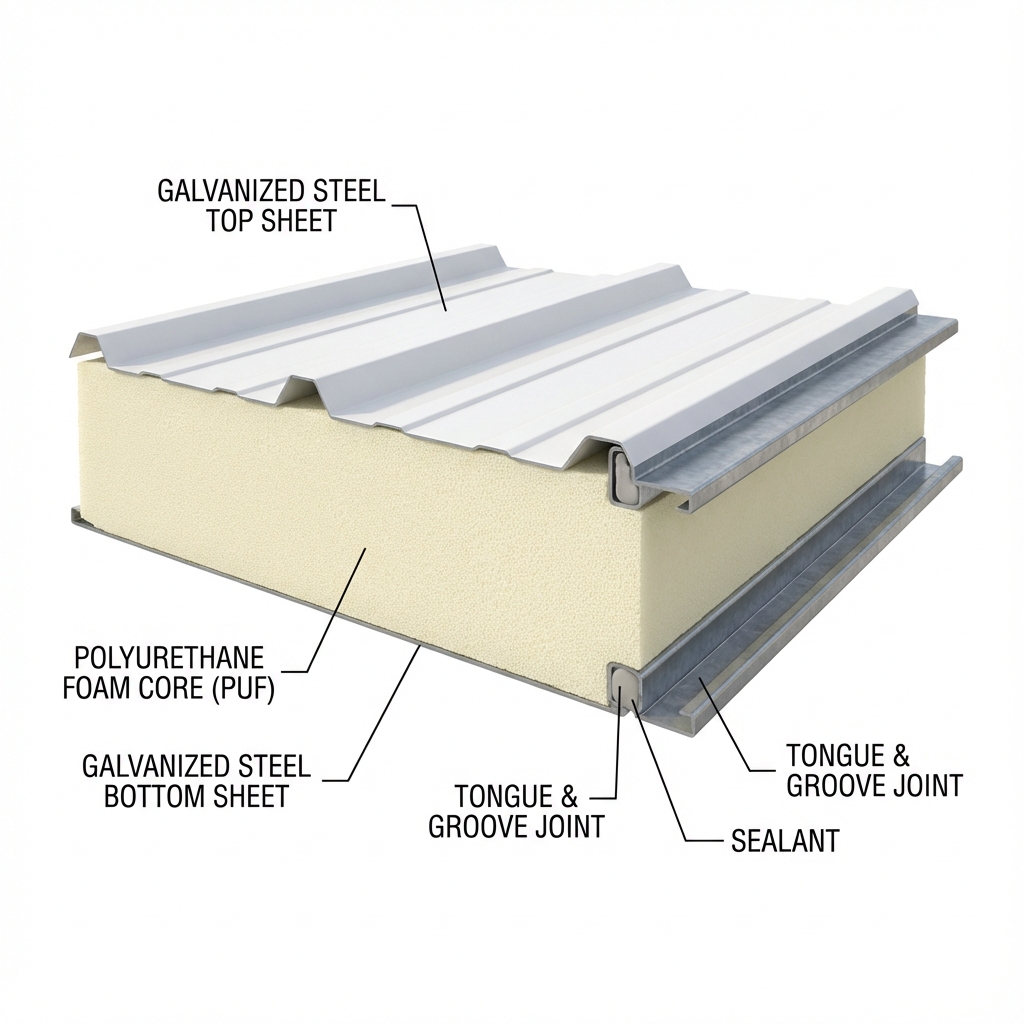

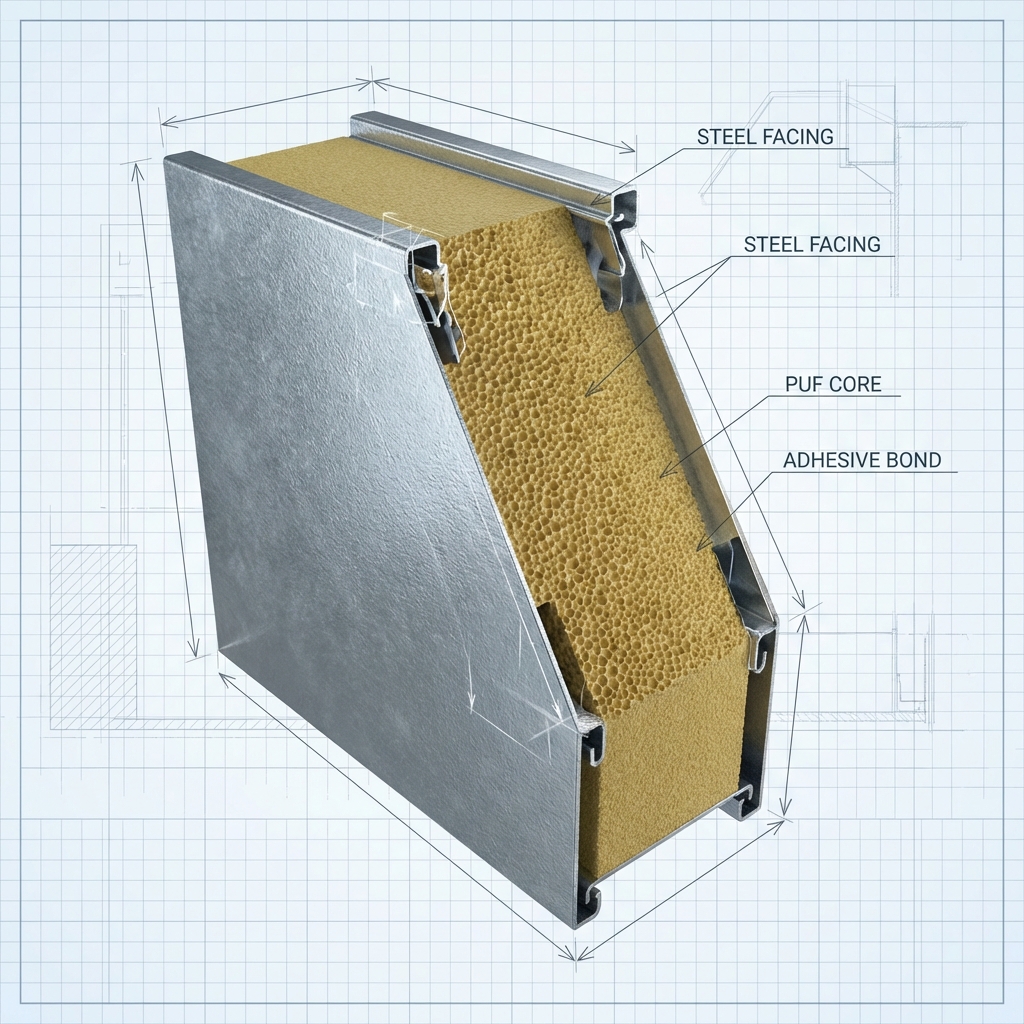

A PUF Sandwich Panel (Polyurethane Foam Sandwich Panel) is a type of insulated building panel widely used in construction, especially for walls, roofs, cold storage, and clean rooms. It consists of two outer metal sheets (usually steel or aluminum) bonded to a polyurethane foam core.

Composition:

- Outer Layers: Usually made of galvanized steel, aluminum, or other metal sheets that provide structural strength and a surface finish.

- Core Material: Polyurethane foam, which offers high thermal insulation by trapping air within its cells. Sometimes, other insulations like PIR or polystyrene are used.

Key Benefits & Resilience

Being water-resistant, these panels also offer fire resistance, thanks to the polyurethane foam that prevents flames from spreading. This makes them an ideal choice for various fire-sensitive industries. PULUX PUF Panels also maintain specific temperatures, making them an energy-efficient and a smart building option.

Advantages:

- High thermal insulation: U-values as low as 0.2 W/m²K, significantly reducing heating and cooling costs.

- Fire Resistance: Can be designed with a fire-retardant core to meet safety standards.

- Moisture and Pest Resistance: The non-porous core resists mold, pests, and moisture ingress.

- Structural Strength: Provides a high load-bearing capacity in many applications.

Applications & Specifications

Typical Applications:

- Warehouses & Industrial Sheds

- Cold storage rooms & Ripening Chambers

- Prefabricated buildings & Site Offices

- Commercial spaces & Showrooms

- Agricultural buildings

Technical Considerations:

- Panel Thickness: Typically ranges from 50mm to 200mm, depending on insulation requirements.

- Size Customization: Lengths can be customized; widths are usually standardized.

- Maintenance: Requires minimal maintenance; periodic cleaning and inspection for damages are typically sufficient.

Keywords: PUF panel for wall, PUF Panel price, Pulux PUF Panel price list, PUF panel house, Puf panels near me, Puf panels sizes.